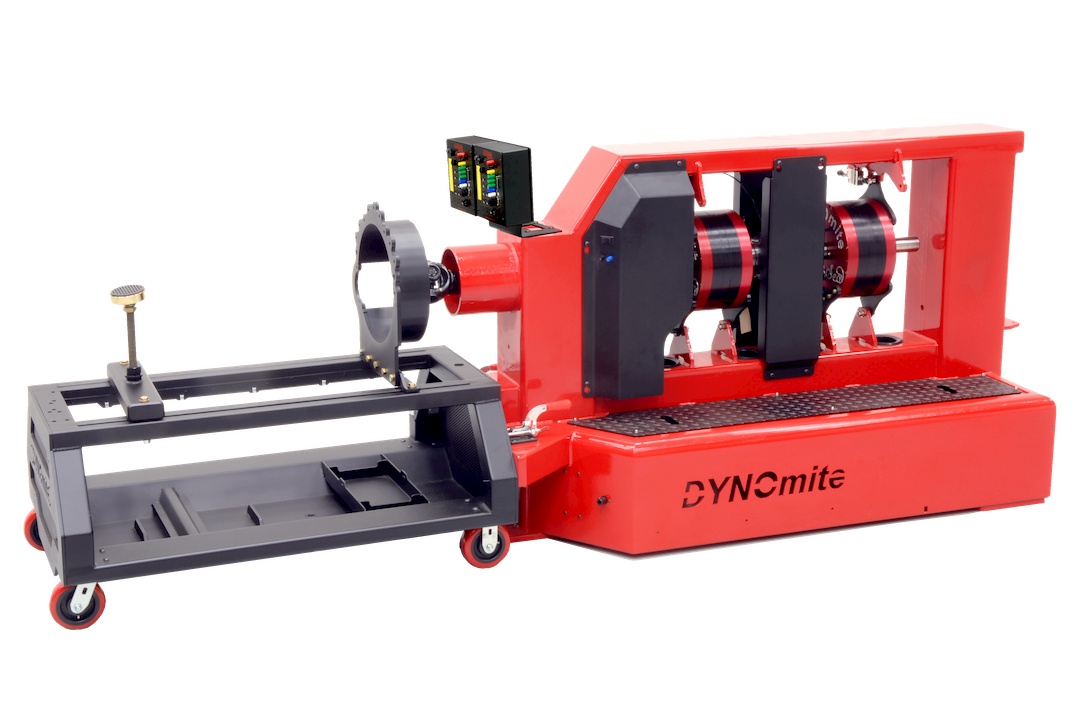

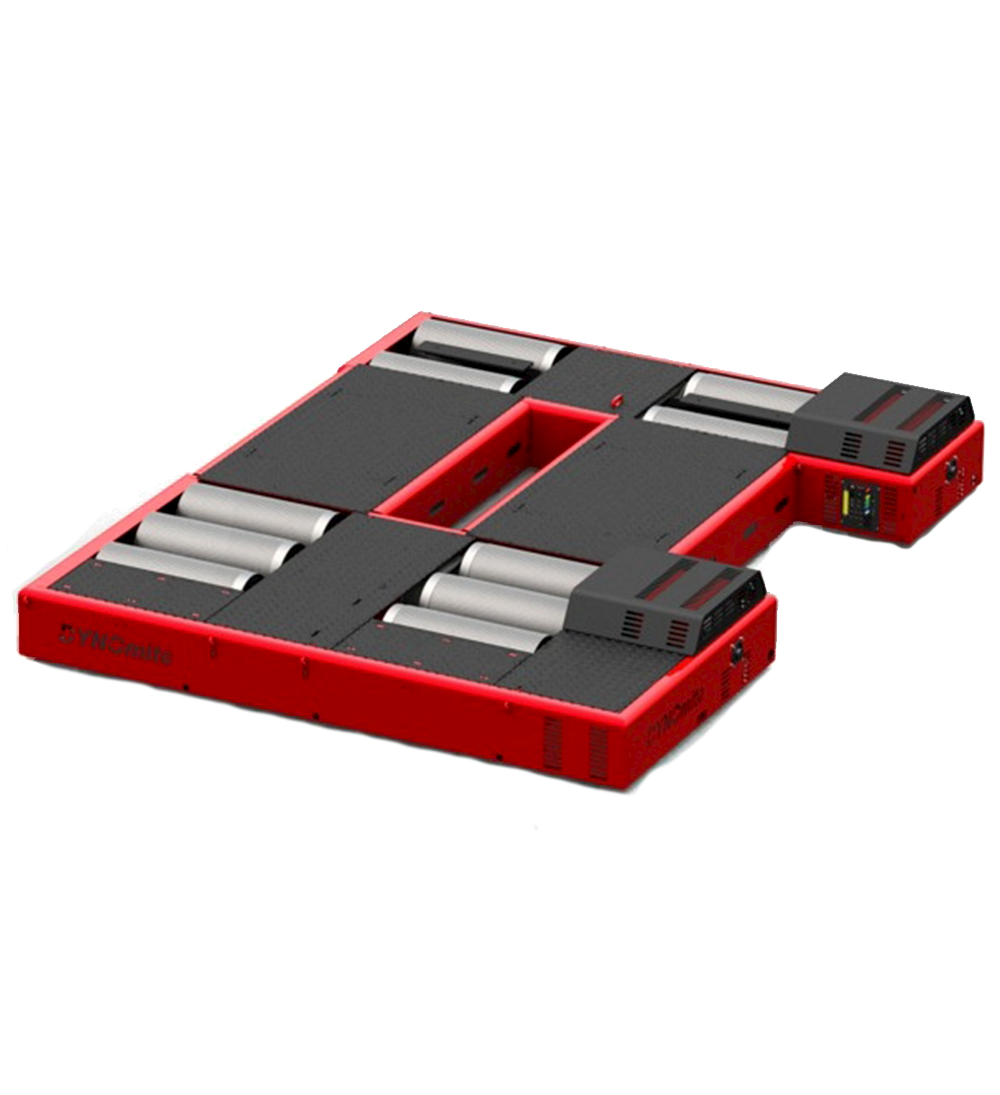

AWD Axle-Hub Dyno

Includes: Four heavy-duty rolling modules with eddy-current controllers and high-speed (medium-inertia) air-cooled absorbers, automatic camber...

Click to learn more.

Products

Explore the world's largest lineup of dynamometers offered by DYNOmite.

Industries

Browse our products by industries served. In many cases we offer several products and solutions across multiple departments.

Absorber Comparison

View charts that explain the advantages of various configurations.